HealthSCREEN UK

Isocyanates Monitoring

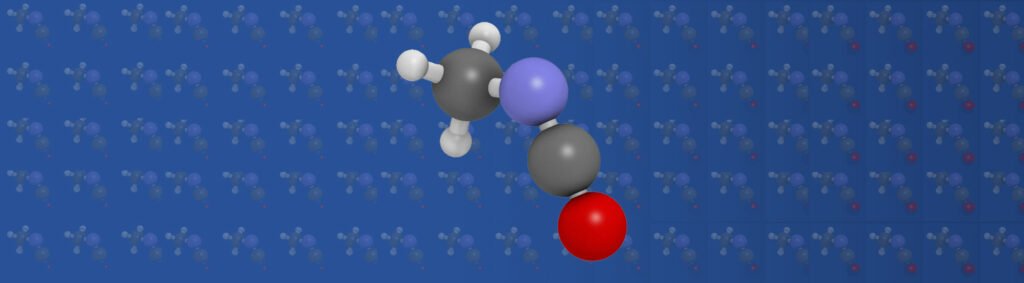

Isocyanates are highly reactive chemicals commonly used in the manufacturing of foams, coatings, adhesives, and other industrial products. However, exposure to isocyanates can pose significant health risks, including occupational asthma. Monitoring isocyanate exposure is crucial to ensure the safety and well-being of employees working with these chemicals.

How We Support You

Our process involves collecting urine samples from employees and analysing them in specialised laboratories.

Urine sampling is a reliable method for evaluating internal exposure to isocyanates. By measuring the levels of isocyanate metabolites in urine, we accurately quantify the absorbed amounts. Our experienced team ensures a safe and confidential process, providing clear instructions to employees for sample collection.

The collected urine samples are sent to state-of-the-art laboratories with stringent quality control measures. Our skilled professionals analyse the samples, interpreting the results and providing detailed reports. These reports identify whether any elevated levels of isocyanate metabolites are present and recommend control measures to mitigate exposure risks and ensure regulatory compliance.

We collaborate closely with you to understand the results and implement effective strategies, such as engineering controls, personal protective equipment, and employee training. Our aim is to create a safe work environment, protect employee health, and ensure compliance with isocyanate exposure regulations.

Main Benefits

Isocyanates monitoring offers several benefits, including:

- Protecting the health of employees exposed to isocyanates.

- Identifying areas with high isocyanate concentrations for targeted control measures.

- Assessing the effectiveness of engineering controls and personal protective equipment (PPE).

- Complying with regulations and standards regarding isocyanate exposure.

- Preventing occupational asthma and other respiratory-related health issues.

- Providing a benchmark for comparing exposure measurement results.

Ensuring Regulatory Compliance

Compliance with regulations is crucial in maintaining a safe working environment and protecting the health of employees. Isocyanates are hazardous substances subject to various regulations and guidelines, including the Control of Substances Hazardous to Health (COSHH) Regulations 2002. By utilising our Isocyanates Monitoring service, organisations can ensure compliance with these regulations, fulfil their legal obligations, and effectively manage the risks associated with isocyanate exposure.

FAQ:

Isocyanates are a leading cause of occupational asthma. Monitoring helps keep exposure levels as low as reasonably practicable, ensuring the use of appropriate respiratory protective equipment and minimizing health risks.

Isocyanates are widely used in industries such as spray painting, foam manufacturing, polyurethane production, and adhesive manufacturing. They are prevalent in products such as two-pack spray paints, glues, plastics, and polyurethane coatings.

Biological monitoring involves analysing breakdown products of isocyanates in urine samples. It provides an accurate measure of how much isocyanate has entered a person’s body, allowing assessment of the effectiveness of control measures.

If you are concerned about isocyanate exposure in your workplace or require isocyanates monitoring services, contact us at Healthscreen. We offer comprehensive biological monitoring analysis for various isocyanates across the United Kingdom. By monitoring isocyanate exposure and implementing effective control measures, you can ensure the safety and well-being of your employees. Take a proactive step towards creating a healthier work environment by contacting us today.

Isocyanates – What They Are and Why You Should Look Out For Them

Isocyanates Monitoring – What It Is and Why It’s So Crucial To Look Out For What are Isocyanates? Isocyanates are a family of highly

What is Biological Monitoring in Industry?

Learn about what Biological Monitoring can offer your company through this handy article:

The First Wealth is Health… Isocyanates exposure

If your employees are exposed to Isocyanates you need to know how to protect them, Healthscreen UK offers this handy guide to give you the information you need: