Musculoskeletal disorders (MSDs):

- Work-related upper limb disorders (WRULDs) from repetitive tasks.

- Back injuries from repetitive or awkward lifting.

WRULDs are chronic (persistent) injuries such as tenosynovitis and carpal tunnel syndrome which result from repetitive tasks on production lines. WRULDs account for around 23% and Chronic back pain accounts for around 35% of cases in occupational ill health in food and drink manufacture. These can stem from repetitive or awkward lifting (e.g. on packing lines, production lines).

Main causes of musculoskeletal injury.

In the food and drink industries, most musculoskeletal injuries arise from just 5 causes:

- cutting, boning, jointing, trussing, and evisceration (such as meat and poultry).

- packing products (such as cheese, confectionery, and biscuits).

- stacking/unstacking containers (such as boxes, crates, and sacks).

- handling drinks containers (such as the delivery of casks, kegs, and crates).

- pushing wheeled racks (such as oven racks and trolleys of produce).

These are key tasks to which attention should be paid when carrying out risk assessments.

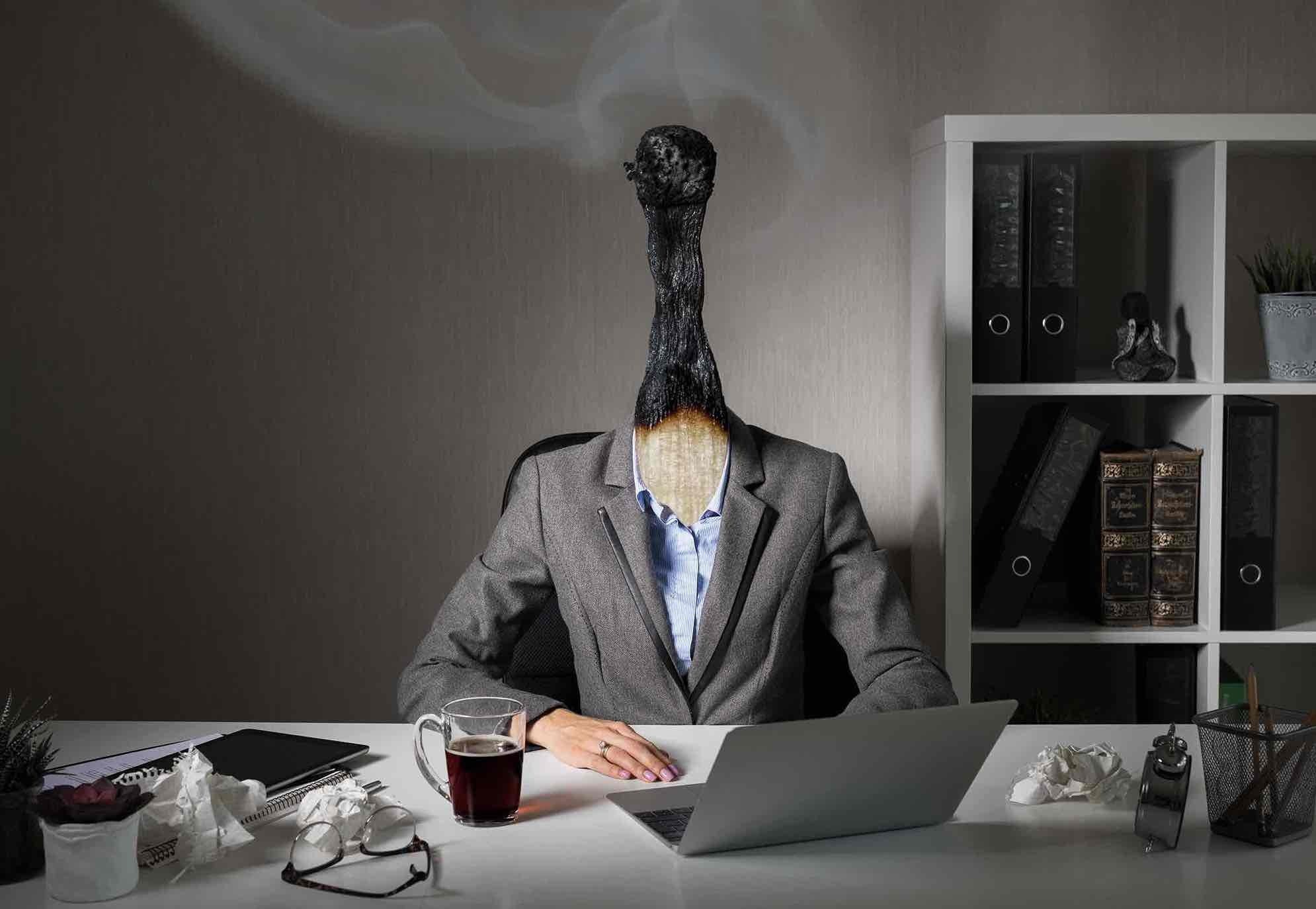

How do we know if we have a problem?

Injury and health problems show up in different ways, such as:

- cases of injury to backs and limbs aches and pains.

- poor product quality high material waste.

- low output frequent worker complaints and rest stops.

- do-it-yourself improvements to work stations and tools (e.g.seat padding).

- workers wearing bandages, splints, rub-ons, copper bracelets or magnets.

Having issues with sickness absence, high staff turnover, retraining causes a loss of production and is very costly to the business’. Looking after your employees is key to helping them stay healthy and can support your business.

Managing the risk

Identify which tasks present a serious risk of chronic injury (e.g.from repetitive upper bodyworker frequent bending). Assess these tasks in detail to decide what factors lead to the risk Introduce mechanization where this is reasonably practicable,e.g. automation, bulk handling, vacuum lifters.

Where mechanization is not possible, introduce measures to prevent injury, e.g. improved ergonomic design of work stations and work areas, job rotation, training, medical surveillance, job transfer Consult fully with trade union safety representatives or other employees representatives and workers to ensure effective and workable solutions to problems.

Visit our website for more advice or call us today to book an onsite Musculoskeletal screening day.